In the field of oil drilling and non-excavation engineering, solid control equipment plays a vital role. The normal operation of solid control equipment can not be separated from the support of various spare parts. Understanding the spare parts of the solid control equipment is of great significance to ensure the efficient operation of the equipment, reduce the maintenance cost and improve the operational safety. In this paper, we will introduce the spare parts of solid control equipment in detail.

Overview of solid control equipment

Solid control equipment plays a pivotal role in oil drilling, non-excavation engineering and other fields. It is mainly used to control the solid-phase content in drilling fluids, ensure stable performance of drilling fluids, and provide a strong guarantee for safe and efficient drilling operations. Solid control equipment usually consists of several units with different functions, which work together to complete the separation and processing of solid-phase particles in drilling fluid. Among them, the vibrating screen is the first line of defence of the solid control equipment, which separates the larger particles of rock chips from the drilling fluid through high-frequency vibration. Sand remover and mud remover further remove fine sand and mud particles from the drilling fluid to make the drilling fluid purer. Centrifuges, as the high-end equipment in the solid control equipment, can efficiently separate tiny solid-phase particles and further improve the quality of drilling fluid. During drilling operations, the drilling fluid will continuously circulate and carry solid-phase particles such as rock chips from the bottom of the well back to the surface. Solid-phase control equipment is installed in the drilling fluid circulation system to process the returned drilling fluid in real time. By continuously separating the solid-phase particles, the solid-control equipment can effectively control the density, viscosity and sand content of the drilling fluid, so that it always stays within the appropriate range to meet the requirements of the drilling process.

The performance of solid control equipment directly affects the efficiency and quality of drilling operations. Efficient solid-control equipment can reduce the solid-phase content in the drilling fluid, lower the frictional resistance of the drilling fluid, and increase the drilling speed. At the same time, it can also reduce the wear and tear of drilling equipment, extend the service life of the equipment and reduce drilling costs. In addition, good solid control equipment can also improve the stability of drilling fluid, reduce the occurrence of downhole accidents, and ensure the safety of drilling operations.

Importance of spare parts for solid control equipment

Solid control equipment in the long run, there will be a variety of wear and tear, damage and so on. Timely replacement of spare parts can ensure the normal operation of the equipment and avoid downtime and losses caused by equipment failure.

Adequate spare parts inventory can be quickly repaired when equipment failure occurs, improving the reliability and stability of equipment.

Stockpiling spare parts in advance can avoid the urgent purchase of high-priced spare parts when the equipment fails, thus reducing maintenance costs.

Regular replacement of worn spare parts can extend the service life of the equipment and improve the overall efficiency of the equipment.

Solid control equipment common spare parts classification

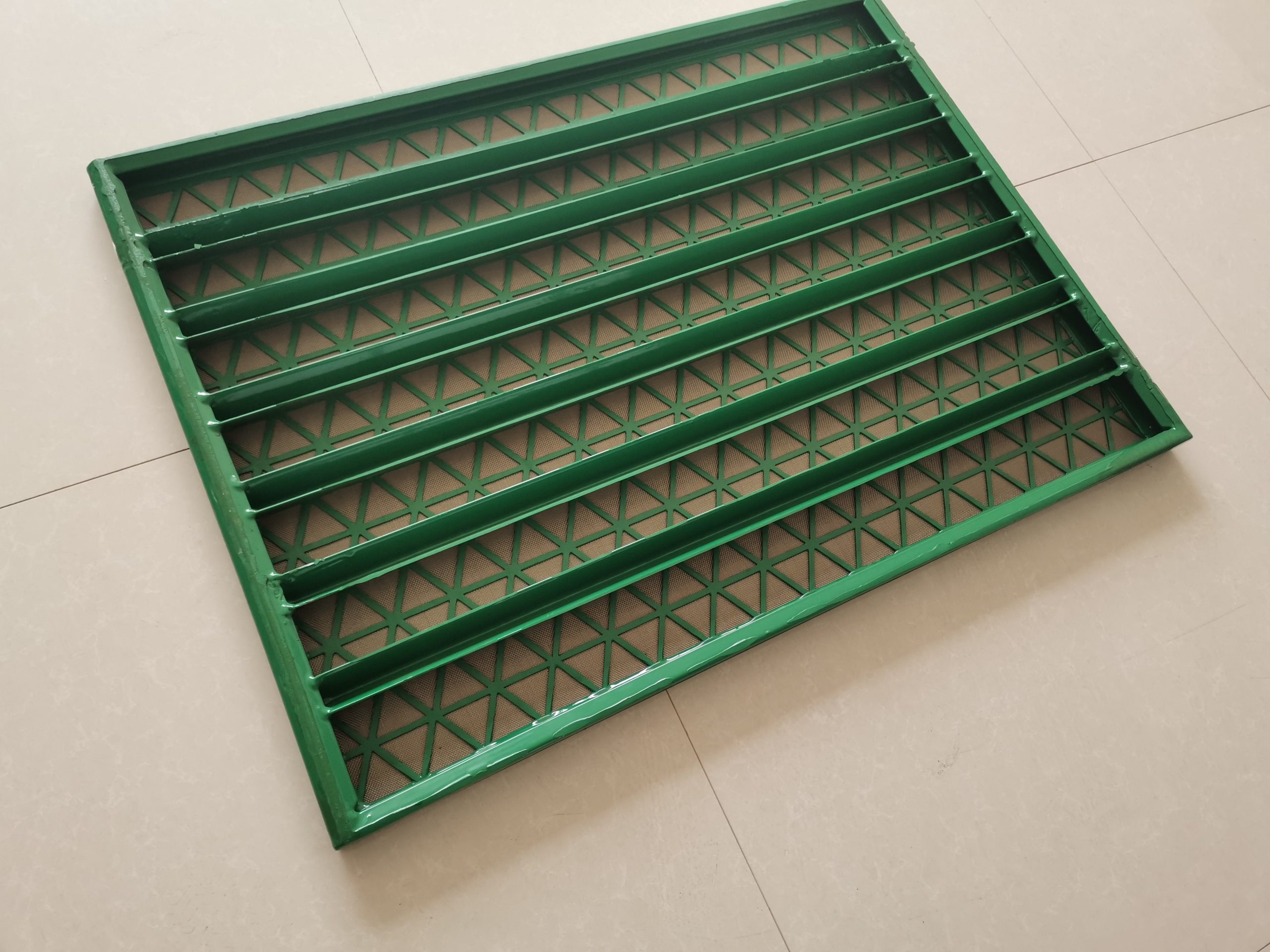

(1) screen

The screen is the core component of the vibrating screen, and its function is to separate the solid-phase particles from the drilling fluid. Factors such as the material, aperture size and shape of the screen mesh will affect the screening effect. Common screen materials include stainless steel, polyurethane and so on.Stainless steel screen mesh has the advantages of high strength and corrosion resistance, but the price is relatively high. Polyurethane screen has the characteristics of good elasticity, wear resistance, etc., and is suitable for dealing with viscous drilling fluid.

(2) Shaker

The exciter is the power source of the vibrating screen, which makes the screen screen screen the drilling fluid by generating high-frequency vibration. The performance of the exciter directly affects the screening effect and service life of the vibrating screen.Common exciters are eccentric block exciter and electromagnetic exciter. Eccentric block exciter structure is simple, high reliability, but the vibration frequency is relatively low. Electromagnetic exciter vibration frequency is high, easy to adjust, but the price is high.

(3) Spring

The spring is a vibrating screen shock absorption component, and its role is to reduce the impact of the vibrating screen on the foundation during operation. The performance of the spring directly affects the stability and service life of the vibrating screen.The common springs are coil springs, rubber springs, etc.. The coil spring has the advantages of strong carrying capacity and good stability, but the price is relatively high. Rubber springs have the characteristics of good elasticity and good shock absorption, and are suitable for occasions with high requirements for shock absorption.

(1) Cyclone

The cyclone is the core component of desander and mud remover, and its function is to use centrifugal force to separate the solid-phase particles in drilling fluid. The material, structure and size of the cyclone will affect the separation effect.Common cyclone materials include polyurethane, ceramic and so on. Polyurethane cyclone has the advantages of wear and corrosion resistance, but the price is relatively high. Ceramic cyclone has the characteristics of high hardness, good abrasion resistance, etc., and is suitable for dealing with hard solid-phase particles.

(2) Bottom flow port and overflow port

Underflow and overflow ports are important components of the cyclone, and their size and shape will affect the separation effect of the cyclone. Wear and tear of the bottom and overflow ports will lead to a decrease in the separation effect, and need to be replaced in time.

(3) Pressure gauge and flow meter

Pressure gauges and flow meters are used to monitor the operating parameters of the desander and desilter, such as pressure and flow rate. The accuracy of these meters directly affects the operating effect and safety of the equipment.

(1) Drum

The drum is the core component of the centrifuge, and its function is to generate centrifugal force through high-speed rotation to separate the solid-phase particles in the drilling fluid. The material, structure and size of the drum will affect the separation effect and service life.Common drum materials include stainless steel, duplex steel and so on. Stainless steel drums have the advantages of high strength and corrosion resistance, but the price is relatively high. Duplex steel drum has high strength, good corrosion resistance and other characteristics, and is suitable for dealing with more corrosive drilling fluid.

(2) Screw conveyor

The screw conveyor is used to discharge the separated solid-phase particles from the centrifuge. The structure and performance of the screw conveyor will affect the slag discharge effect and stability of the centrifuge.

(3) Main bearing and sub-bearing

The main bearing and sub-bearing are key components of the centrifuge, and their function is to support the rotation of the drum. The performance of the bearings directly affects the operating effect and service life of the centrifuge.

Common bearings include rolling bearings and plain bearings. Rolling bearings have the advantages of small friction coefficient, high speed, etc., but the price is relatively high. Sliding bearings have the characteristics of strong bearing capacity and good stability, which are suitable for occasions with high requirements on bearing capacity.

(1) Motor

Motor is the power source of solid control equipment, its performance directly affects the operating effect and reliability of the equipment. Common motors include AC motors and DC motors.

AC motor has the advantages of simple structure, high reliability, relatively low price, but relatively poor speed performance. DC motor with good speed performance, starting torque and other characteristics, but the price is relatively high.

(2) pump

Pump is solid control equipment used to transport drilling fluid equipment, its performance directly affects the operating effect and reliability of the equipment. Common pumps are centrifugal pumps, screw pumps and so on.

Centrifugal pump has the advantages of large flow, high head, but the viscosity of the medium requires high. Screw pumps have a large viscosity of the medium, stable flow and other characteristics, but the price is relatively high.

(3) Valve

Valves are used to control the flow of drilling fluid and flow in the solid control equipment, and their performance directly affects the operating effect and safety of the equipment. Common valves are ball valves, gate valves, butterfly valves and so on.

Ball valves have the advantages of rapid switching and good sealing, but the price is relatively high. Gate valve has a large circulation capacity, good sealing and other characteristics, suitable for the higher requirements of the circulation capacity of the occasion. Butterfly valve has a simple structure, small size and other advantages, but the sealing is relatively poor.

Solid control equipment spare parts selection and management

(1) Selection of spare parts: select suitable spare parts according to the equipment model and specifications, and ensure the compatibility of spare parts with the equipment. Select spare parts with reliable quality and stable performance to avoid equipment failure due to spare parts quality problems. Consider the price of spare parts and cost-effective, choose reasonable price, excellent performance spare parts. According to the use of equipment environment and working conditions to choose the appropriate spare parts material, to ensure that the spare parts of corrosion and wear resistance.

(2) Management of spare parts: Establish the spare parts inventory management system, regularly inventory and clean up the spare parts inventory to ensure the accuracy and reasonableness of the spare parts inventory. Classify and manage spare parts, classify them according to their importance and frequency of use, and formulate different inventory management strategies. Establish the spare parts procurement management system, standardise the spare parts procurement process, and ensure the quality and price of spare parts procurement. Strengthen the maintenance and repair of spare parts, regularly inspect and maintain spare parts to prolong the service life of spare parts.

Spare parts of solid control equipment is an important part of ensuring the normal operation of the equipment. Understanding the types, roles and selection of management methods of solid control equipment spare parts is important for improving the reliability of the equipment, reducing maintenance costs and extending the service life of the equipment. In practical application, suitable spare parts should be selected according to the model, specification and use environment of the equipment, and the management and maintenance of spare parts should be strengthened to ensure the efficient operation of the solid control equipment.