The importance of mud follow-up treatment

In all kinds of engineering construction, mining, drilling operations and other fields, the generation of mud is inevitable. If mud is not properly treated, it will bring many serious problems. Firstly, the discharge of large quantities of untreated mud will cause great damage to the environment, pollute the soil and water sources, and affect the ecological balance. Secondly, the accumulation of mud will take up a large amount of land resources, affecting the efficiency of the use of engineering sites. In addition, in some areas with strict requirements for environmental protection, failure to dispose of mud may lead to fines for project suspension, affecting project progress and economic benefits. Therefore, it is crucial to solve the problem of mud follow-up treatment.

Characteristics of mud and treatment difficulties

Characteristics of mud: Components are complex and varied. Mud is usually composed of water, clay, sand and gravel, chemical additives, etc. The composition of mud from different sources varies greatly. For example, drilling mud may contain a variety of drilling fluid additives, and construction mud may contain cement and other components. It has a certain degree of fluidity and stability. The fluidity of the mud makes it difficult to settle and separate naturally, while the stability makes the mud not easy to break the glue and flocculation in the treatment process.Higher solid content. The slurry has a high content of solid particles, which increases the difficulty and cost of treatment.

Treatment difficulties: solid-liquid separation difficulties. Due to the complexity of the slurry composition and its fluidity and stability, solid-liquid separation becomes a major problem. The traditional natural precipitation method is often ineffective, and advanced slurry equipment is needed for treatment. Strict environmental requirements. Slurry may contain harmful substances, such as heavy metals, chemicals, etc., the treatment process must meet the strict environmental requirements, can not cause secondary pollution of the environment. Large processing capacity and high cost. In large-scale projects, the amount of mud generated is very large, requiring efficient, large-capacity mud equipment for processing, which also leads to an increase in processing costs.

Common mud follow-up treatment methods

Natural precipitation method: the mud is placed in a sedimentation tank, relying on gravity to make the solid particles naturally precipitate. This method is simple and easy to implement, the cost is low, but the processing time is long, covers a large area, and the separation effect for fine particles is not good. Generally applicable to the treatment requirements are not high, the slurry generated a small amount of occasions.

Chemical flocculation method: add flocculants to the slurry, so that the solid particles in the slurry flocculation into a group, to accelerate the precipitation separation. Commonly used flocculants are polyacrylamide and so on. The method has a better treatment effect, but the selection and use of flocculants need to be adjusted according to the nature of the mud, otherwise the treatment effect may be affected. At the same time, the use of flocculants will increase the cost of treatment and may have a certain impact on the environment.

Mechanical separation method: the use of a variety of slurry equipment to mechanically separate the slurry is currently a more commonly used treatment method. Mechanical separation method can quickly and effectively achieve solid-liquid separation, high processing efficiency, and can be based on different mud properties to choose the appropriate equipment and process.

Slurry equipment to solve the subsequent treatment of slurry

Plate and frame filter press

Plate and frame filter press consists of alternately arranged filter plates and frames to form a set of filter chambers. Under the pressure of the feed pump, the slurry is fed into the filter chamber, the solid particles are retained by the filter cloth, and the liquid is discharged through the filter cloth. As the filtration proceeds, the filter cake gradually thickens, and when it reaches a certain thickness, the feeding is stopped and the dewatering is carried out by pressing, so that the moisture content of the filter cake is further reduced.

(1) Good dewatering effect. It can remove a large amount of water in the slurry, so that the water content of the mud cake is reduced to a low level.

(2) Strong adaptability. It can deal with mud of different properties, including high concentration and high viscosity.

(3) Simple operation. The structure of the equipment is relatively simple, easy to operate and easy to maintain.

3 Disadvantages

(1) Intermittent operation. Can not be continuous operation, processing efficiency is relatively low.

(2) Large floor space. Due to the large size of the equipment, a larger installation space is required.

Belt filter press

Belt filter press by the upper and lower two tensioned filter belt clamped slurry forward movement, in the process of movement, the slurry by gravity, wedge zone pressure, squeeze zone pressure and shear force, etc., to achieve solid-liquid separation.

(1) Large treatment capacity. Capable of continuous operation and high processing efficiency, it is suitable for processing a large amount of mud.

(2) High degree of automation. Automatic control can be achieved during the operation of the equipment, reducing manual operation.

(3) Small footprint. Compared with plate and frame filter press, it occupies a smaller area.

3 Disadvantages

(1) The filter belt is easy to wear. As the filter belt is constantly subject to friction during operation, it is easy to wear out and needs to be replaced periodically.

(2) Sensitive to changes in slurry properties. When there is a big change in the nature of the mud, it may affect the treatment effect.

Centrifuge

Centrifuges use centrifugal force to separate the solid and liquid phases in the mud. Inside the high-speed rotating drum, solid particles are thrown towards the inner wall of the drum due to centrifugal force, forming a sedimentation layer, while the liquid is discharged from the centre of the drum under the effect of centrifugal force.

(1) High separation efficiency. It can realise solid-liquid separation quickly and effectively.

(2) Large processing capacity. It can be operated continuously and is suitable for large-scale mud treatment.

(3) Small footprint. The equipment structure is compact and occupies little space.

3 Disadvantages

(1) Higher energy consumption. Due to the need for high-speed rotation, energy consumption is relatively large.

(2) Higher equipment price. The manufacturing and maintenance costs of centrifuges are high.

Cyclone

Cyclone is a kind of equipment that uses the principle of centrifugal sedimentation for separation. The slurry enters the cyclone tangentially with a certain pressure and speed, and under the action of centrifugal force, the heavier solid particles are thrown to the wall and move downward under the action of gravity, and are discharged from the bottom flow port; the lighter liquid forms an internal cyclone and is discharged from the overflow port.

(1) Simple structure. The equipment is small in size, light in weight and easy to install.

(2) High processing efficiency. It can quickly separate solid particles and liquid in the slurry.

(3) Low cost. The price of the equipment is relatively low, and the running cost is not high.

3 Disadvantages

(1) Limited separation precision. The separation effect for fine particles is not as good as other equipment.

(2) Easy to clog. When the slurry contains large particles or debris, it is easy to clog the cyclone.

Decanter centrifuge

Decanter centrifuge is a horizontal spiral discharge sedimentation centrifuge. Slurry from the inlet into the drum, in the high-speed rotation of the drum, due to the role of centrifugal force, solid particles are thrown to the inner wall of the drum, the formation of sedimentation layer, while the liquid under the action of centrifugal force from the centre of the drum discharged. The solid particles settled in the inner wall of the drum gradually move towards the small end of the drum under the push of the spiral, and are discharged from the slag discharge port.

(1) Large treatment capacity. It can be operated continuously with high processing efficiency.

(2) Good separation effect. It can effectively separate the solid particles and liquid in the slurry, and the separation precision is high.

(3) High degree of automation. Automatic control can be achieved during the operation of the equipment, reducing manual operation.

3 Disadvantages

(1) Higher equipment price. The manufacturing and maintenance costs of decanter centrifuge are high.

(2) More sensitive to changes in mud properties. When there is a big change in the nature of the mud, it may affect the treatment effect.

Selection and application of mud equipment

Selection of equipment according to the nature of mud: the nature of mud from different sources varies greatly, so when selecting mud equipment, you need to select according to the composition, concentration, viscosity and other properties of the mud. For example, for high concentration, high viscosity slurry, you can choose plate and frame filter press or belt filter press; for more fine particles of slurry, you can choose centrifuge or cyclone.

Select equipment according to the processing requirements: different projects have different requirements for the treatment of slurry, for example, some projects require a lower water content of the mud cake, at this time you can choose the plate and frame filter press or belt filter press with good dewatering effect; some projects require high processing efficiency, you can choose centrifuges or decanter centrifuges.

Comprehensive consideration of cost factors: in the choice of slurry equipment, you also need to consider the purchase cost of equipment, operating costs, maintenance costs and other factors. Generally speaking, the higher price of equipment centrifuge and decanter centrifuge processing efficiency, but the operating cost is also relatively high; while the lower price of cyclone and plate and frame filter press processing efficiency is relatively low, but the operating cost is also low.

Future development trend

Intelligent development

With the continuous progress of science and technology, mud equipment will be developed in the direction of intelligence. Future slurry equipment will have automated control, remote monitoring, fault diagnosis and other functions, can achieve unattended operation, improve processing efficiency and reduce operating costs.

Energy saving and environmental protection

In the context of increasingly stringent environmental requirements, mud equipment will pay more attention to energy saving and environmental protection. Future slurry equipment will use more advanced energy-saving technology to reduce energy consumption; at the same time, it will also use more environmentally friendly processing technology to reduce pollution of the environment.

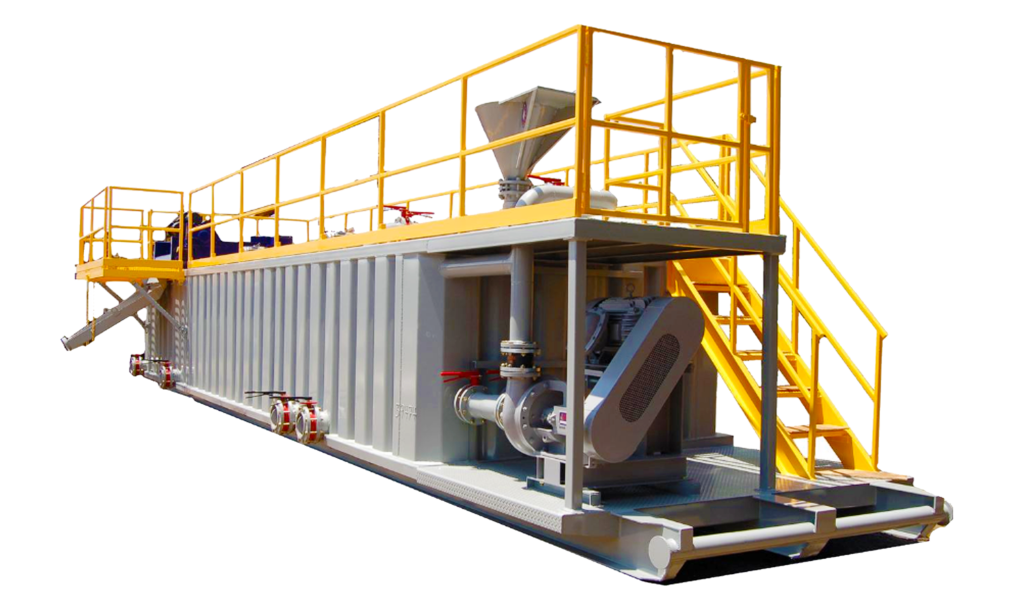

Multifunctional integration

In order to improve the efficiency of the equipment and reduce costs, the future of the mud equipment will be towards the direction of multi-functional integration. For example, solid-liquid separation, dewatering, drying and other functions are integrated in one equipment to achieve one-stop processing.

Mud follow-up treatment is an important and complex work, which requires the selection of appropriate treatment methods and mud equipment. Different mud equipment has its own advantages and disadvantages, the choice needs to be based on the nature of the mud, treatment requirements and cost factors for comprehensive consideration. With the continuous progress of science and technology, the mud equipment will move towards the direction of intelligent, energy-saving and environmental protection, multi-functional integration, to provide a more efficient and reliable solution for the subsequent treatment of mud.