Screen selection is an essential factor in material processing. It refers to the careful and precise choice of screens used for separating different sizes of materials during a screening process. Material processing involves various industries such as construction, mining, agriculture, and recycling, among others.

The success of these industries depends on their ability to separate materials accurately and efficiently. Screen selection determines the quality and quantity of the end product, making it a critical factor for optimal material processing.

In this article, we will discuss the importance of screen selection and how it impacts material processing. We will also explore different factors that influence screen selection and their effects on the screening process.

Screen selection involves choosing the right type of screen for a specific material processing application. It is a crucial aspect of the screening process as it affects the efficiency and productivity of material separation.

The primary purpose of screen selection is to classify materials according to their size, shape, and composition. This classification ensures that the desired product is separated from unwanted particles, debris, or contaminants.

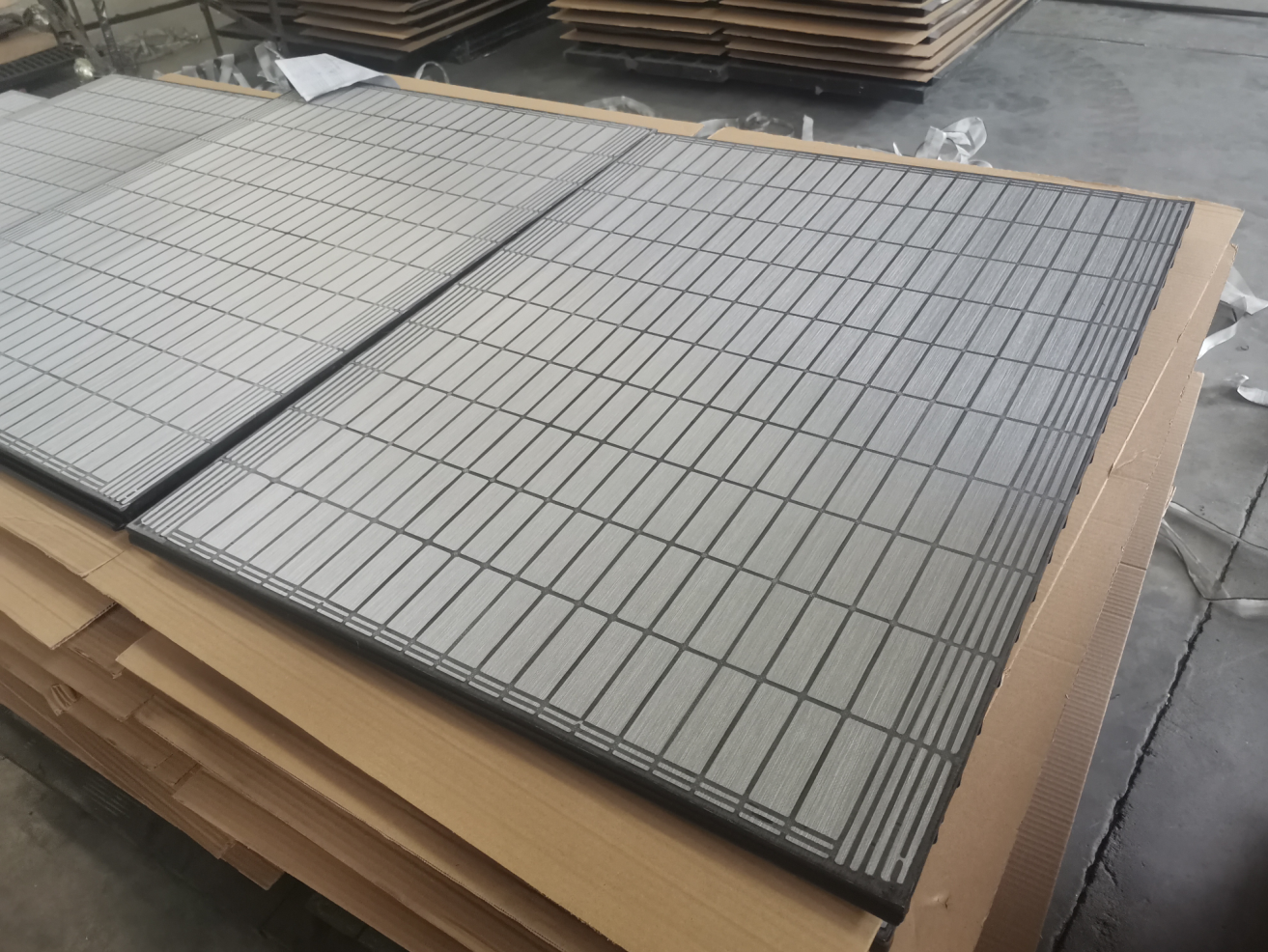

There are various types of screens available for different material processing applications, such as vibrating screens, trommel screens, and flip-flow screens. Each screen has its unique design, size, and configuration to cater to specific requirements. Some factors that influence screen selection include the type of material being processed, particle size distribution, capacity requirements, and environmental conditions.

Screen selection plays a crucial role in achieving optimal material processing. The correct type of screen can significantly impact the production rate, quality, and cost-effectiveness of the screening process.

One of the key reasons why screen selection is critical is its direct effect on the accuracy and efficiency of material separation. A properly selected screen can accurately separate the desired product from unwanted particles, resulting in a high-quality end product.

Moreover, screen selection also affects the overall productivity of material processing. The right type of screen can handle a higher capacity and reduce downtime due to clogging or overloading. This leads to increased production rates and cost savings for the industry.

Additionally, choosing the appropriate screen also ensures the durability and longevity of the screening equipment. Different materials have varying levels of abrasiveness, corrosiveness, or moisture content, which can affect the screen’s performance. By selecting a suitable screen for a specific material, it can withstand the harsh processing conditions, reducing maintenance costs and prolonging its lifespan.

Another crucial factor influenced by screen selection is energy consumption. The type of screen used can impact the amount of energy needed for material separation. A well-selected screen can save on energy costs and make the screening process more sustainable.

Considering the significant impact of screen selection on material processing, it is crucial to pay close attention to this factor. Proper screen selection not only ensures optimal performance but also minimizes downtime and maximizes cost savings.

Moreover, different materials require specific screens for efficient separation, and using the wrong type of screen can result in poor quality end products or equipment damage. Therefore, it is essential to consult with experts and consider the material type, size distribution, capacity requirements, and environmental conditions when selecting screens for material processing.

Additionally, regularly monitoring and evaluating the performance of screens can help identify any issues or changes in material characteristics that may require a different screen selection. This practice can improve overall productivity and maintain the quality of materials processed.

Screen selection not only affects material processing but also other industries that rely on accurate separation of different materials. For example, the construction industry requires properly selected screens to produce high-quality aggregates for building purposes.

Mining and quarrying industries need efficient screen selection to extract valuable minerals and separate them from unwanted rocks or soil.

Furthermore, agriculture and food processing industries need screens to separate grains or crops from debris, ensuring the safety and quality of their products.

Also, the recycling industry heavily relies on screen selection to separate different types of materials in the recycling process. Proper screening can result in a higher yield of recycled products and improve sustainability efforts.

Neglecting proper screen selection can result in various risks that can hamper the success of material processing. Using the wrong type of screen can lead to excessive downtime, reduced productivity, and increased maintenance costs.

Moreover, inaccurate material separation due to improper screen selection can result in poor quality end products, leading to customer dissatisfaction and potential damage to the industry’s reputation.

The use of incorrect screens can also pose safety hazards for workers, such as equipment malfunction or exposure to harmful materials. This can lead to negative impacts on employee morale and overall workplace efficiency.

Furthermore, neglecting screen selection can result in increased energy consumption, leading to higher operating costs and a larger carbon footprint. In today’s world, where sustainability is a growing concern, industries must consider all aspects of their operations to minimize their environmental impact.

To ensure optimal screen selection, it is crucial to consult with experts and consider various factors before making a decision. Some tips for selecting the right screens for material processing include:

By considering these tips and consulting with experts, industries can ensure optimal screen selection for their material processing needs. This not only results in efficient operation and cost savings but also contributes to overall sustainability efforts.

Screen selection plays a crucial role in material processing as it directly impacts the performance, productivity, and cost efficiency of the process. Proper screen selection ensures accurate separation of materials, reducing downtime and maintenance costs.

Yes, improper screen selection can impact other industries such as construction, mining, agriculture, food processing, and recycling. These industries rely on accurate material separation for their operations and product quality.

Neglecting proper screen selection can result in excessive downtime, reduced productivity, poor product quality, safety hazards for workers, increased energy consumption, and higher operating costs.

Understanding material characteristics, considering capacity requirements, evaluating environmental conditions, and regular monitoring and maintenance are crucial factors to consider when selecting screens for material processing. Consulting with experts can also help in making the right decision.

Screen selection is a critical aspect of material processing that can impact various industries beyond just the processing itself. Neglecting proper screen selection can result in multiple risks and inefficiencies, while following expert tips can ensure optimal performance and sustainability. It is essential for industries to prioritize screen selection to achieve their production goals and maintain high-quality materials.

So, it is crucial that industries pay attention to screen selection and consult with experts to ensure the best results for their material processing needs. By doing so, they can achieve efficient operations, cost savings, and contribute to overall sustainability efforts. Therefore, proper screen selection should always be a top priority for industries in all sectors that rely on material processing.

With expert advice and careful consideration of various factors, industries can reap the benefits of optimal screen selection and drive towards a more sustainable future.